In recent years, the use of digital technologies has revolutionized the way that businesses operate, allowing for increased efficiency, flexibility, and innovation. Two key technologies that have emerged in this context are the digital thread and the digital twin. The digital thread is a continuous, end-to-end digital representation of a physical product or process, linking together all of the data and information related to that product or process. The digital twin, on the other hand, is a digital representation of a physical object or system, created by integrating data from various sources in order to simulate and analyze its behavior and performance.

Together, these technologies have the potential to transform the way that information systems are used in the manufacturing industry, and beyond. In this blog, we will explore the concept of the digital thread and digital twin .Also discuss the benefits and challenges of implementing these technologies in the context of information systems.

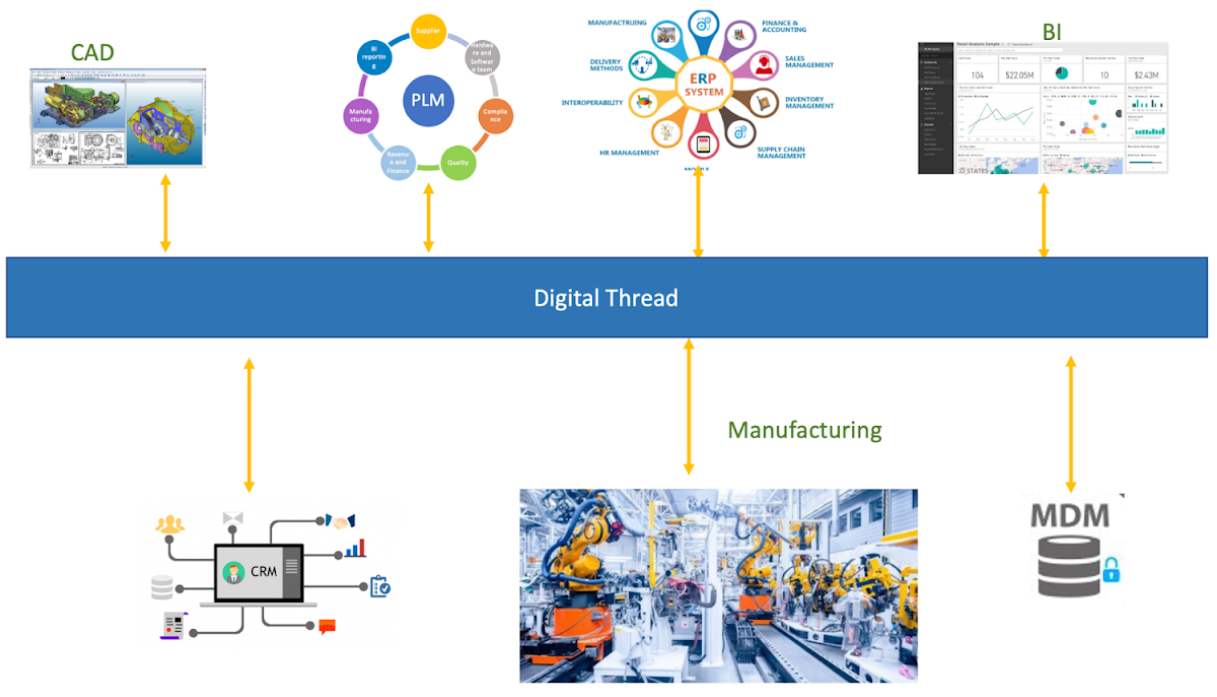

The digital thread is a digital representation of the entire life cycle of a product or process from its design and development, through its manufacture and use, to its maintenance and eventual disposal. It links together all of the data and information related to that product or process, enabling a comprehensive and integrated view of its entire lifecycle.

The digital thread is created by collecting and integrating data from a variety of sources, including design and engineering documents, manufacturing and maintenance records, and sensor data. This data is then used to create a digital model of the product or process, allowing for the simulation and analysis of its behavior and performance.

The digital thread can be used to support a range of activities, including:

The digital twin is a digital representation of a physical object or system, created by integrating data from a variety of sources in order to simulate and analyze its behavior and performance. This includes data from design and engineering documents, as well as sensor data and other real-time data sources.

The digital twin is used to simulate the behavior and performance of the physical object or system in different scenarios, allowing for the analysis and optimization of its performance. This can be used to support a range of activities, including:

The digital thread and digital twin have the potential to bring significant benefits to organizations, particularly in the context of information systems. By providing a continuous, end-to-end digital representation of a product or process, these technologies can help organizations to streamline their operations, improve the quality of their products, and enhance collaboration. However, implementing these technologies also involves a number of challenges, including the need to ensure the quality and integrity of the data used to create them, the technical complexity of integrating new systems and processes, and the need to manage organizational change. Despite these challenges, the digital thread and digital twin offer a promising opportunity for organizations looking to transform their operations and drive innovation in the digital age.